Industrial Hygiene Services That Identify Hazards and Protect Your Workforce

We provide comprehensive sampling, monitoring and exposure assessments for air, dust, noise, heat, and other hazards. Our experts help your facility meet OSHA, federal, and state requirements while keeping your teams safe and your operations compliant.

Industrial Hygiene That Strengthens Workplace Safety

Our certified industrial hygienists and EHS professionals uncover hidden hazards and provide clear guidance to help prevent exposures, reduce risk, and support ongoing OSHA, state, and federal compliance across your facility.

582+

20

450k

800

Industrial Hygiene Designed for Real-World Work Environments

Our assessments help facilities understand exposures, protect workers, and stay compliant with environmental and safety regulations.

Our expertise covers:

-

Air and dust sampling for OSHA exposure limits

-

Noise monitoring and hearing conservation requirements

-

Heat stress evaluations for high-temperature work

-

Chemical and fume exposure assessments

-

Indoor air quality concerns for multiple industries

-

Facilities preparing for audits or regulatory reviews

“Prompt and professional! SCT provides technicians in a timely manner when urgently needed. Not to mention almost instant support for industrial hygiene services.”

Executive

Lilja Corp.

Accurate Testing and Clear Guidance for Safer Workplaces

Our industrial hygiene evaluations deliver precise data and actionable recommendations to help you reduce exposures and maintain safe, compliant operations.

What we bring to your operation:

-

Comprehensive sampling and monitoring

-

Testing for air, dust, noise, heat and chemical hazards

-

Clear reports that support OSHA compliance

-

Recommendations tailored to your facility/site and processes

-

Support for corrective actions and engineering controls

-

Guidance that protects workers and improves safety performance

A Proven Industrial Hygiene Process That Supports Compliance

Site and Hazard Review

We evaluate your processes and exposure risks to identify testing needs.

Sampling and Monitoring

We conduct accurate air, dust, noise, or heat measurements based on site conditions.

Data Analysis and Findings

We analyze results and compare exposure levels against OSHA, federal, and state standards.

Improvement Actions

We provide clear, practical steps to reduce hazards and support compliance.

Industrial Hygiene for High-Hazard and Industrial Operations

Construction

Support for projects of all sizes, from ground-up builds to maintenance and complex infrastructure work. Reduce delays, injuries, and compliance risks with on-site experts who know construction inside and out.

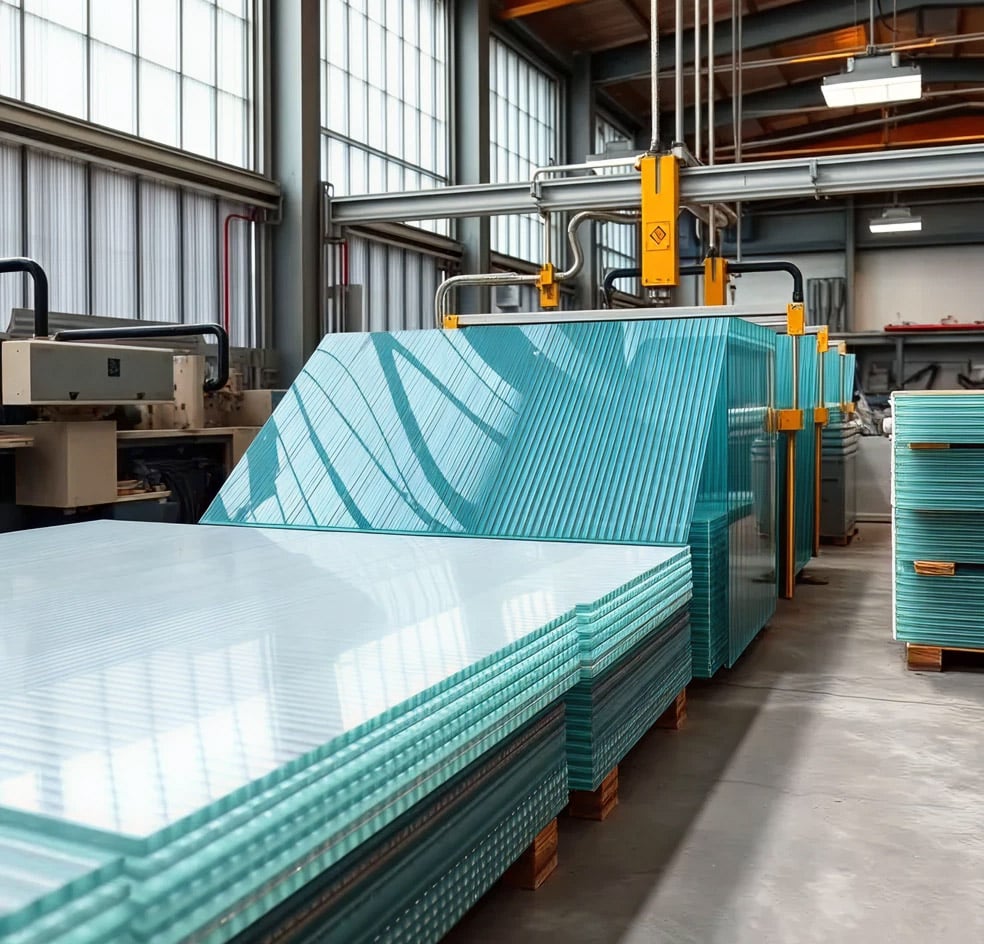

Glass Manufacturing

Specialized expertise in furnace rebuilds, hot and cold repairs, batch operations, and high-temperature environments. We help glass manufacturers prevent downtime, maintain compliance, and keep teams safe around the toughest hazards.

Manufacturing

From food processing to heavy industrial, we strengthen workflows with safety programs, oversight, training, and staffing that keep your operation productive and protected.

General Industry

Scalable safety and environmental services for warehouses, logistics, distribution centers, and industrial facilities, built to improve performance and reduce incident rates.

A Partner Who Works Alongside Your Safety Team

Our experts collaborate with your supervisors, maintenance teams, and EHS staff to understand your environment, improve controls, and strengthen long-term exposure prevention.

-

Collaborative support with clear communication

We work closely with your supervisors and EHS team to share findings, answer questions, and keep everyone aligned throughout the assessment process.

-

Assessments aligned with your operations

Our evaluations reflect your equipment, tasks, workflows, and exposure risks so your results are accurate and meaningful for your facility.

-

Guidance that improves safety and compliance

We provide practical steps that help reduce exposure, strengthen controls, and support ongoing OSHA and regulatory compliance.

Explore Our Other Safety Solutions

Safety Consulting

Safety Staffing

Proactive audits, inspections, and assessments that help you identify hazards before they cause downtime, injuries, or compliance issues.

Safety Training

Expert-led safety courses delivered at your facility or site, designed to strengthen your workforce’s knowledge, compliance, and real-world readiness.

Frequently asked questions

Find answers to your questions about our service and industry options.

Still have questions?

We’re here to help every step of the way.